3D printer and 3D printing. Design becomes quick and fluid

The 3D printer and its immense possibilities have quickly converted from a hobby-level toy into an industrial tool.

What are the characteristics that led to this evolution? How is the industry taking advantage of the 3D printer?

Let's find out together.

3D printer, 3D printing history

![]()

Invented in 1986 by Chuck Hull under the name of "stereolithography", it was immediately seen as a technology that would change the future, impacting both the prototyping and production phases, allowing the creation of "on demand" pieces, even in minimal quantities.

The best definition of the potential of this technology comes from its inventor, who will define it this way:

“A system for generating three-dimensional objects based on the creation of a transversal model of the object to be constituted, on the surface of a fluid medium capable of altering its physical state in response to synergistic stimuli such as incident radiation, particle bombardment or chemical reactions, in adjacent laminae representing successive adjacent cross-sections of the object that integrate with each other, providing for progressive growth by apposition of the desired object, whereby an object is created from a substantially planar surface of the fluid medium during the formation process. ”

In the following thirty years, 3D printing would undergo a rapid evolution, held back only by an economic obstacle, the presence of a patent. The expiration of the same in 2009 will then lead to a technological and productive explosion that will lead this technology to become what it is now.

What is 3D printing?

3D printing also known as additive manufacturing is a new type and technology of manufacturing objects. 3D printing can be considered as the opposite of traditional construction and manufacturing techniques.

In fact, when creating an object in a "traditional" way, we usually start from an existing "raw" piece. The same is then dug and worked by hand or with machinery until the required shape is obtained. In additive printing, however, the required object is created by adding layer after layer.

For this reason this technology is called "additive", because starting from scratch it adds material until reaching the traditional appearance and shape.

This technology is also known as 3D printing as it transforms something printed on paper or present on a file (therefore in 2D) by adding a third dimension, that of depth.

How does the 3D printer work?

At the basis of everything there is a technical drawing, usually created in CAD. The same is processed using dedicated software which creates a "3D rendering" and "cuts it into layers".

After this virtual stratification the printing phase begins.

3D printing materials

There are many 3D printing materials; in fact, you can work with any product that can be dissolved or softened in such a way as to pass through the printing nozzle. Once the printing has been carried out, the product then begins its drying process which can be natural (drying) or totally or partially artificial (via chemicals or UV).

The materials are constantly evolving and range from classic thermoplastics to more unusual materials, such as epoxy resins, some metals, special cement mortars, photopolymers but also vegetable inks, chocolate and spreadable creams in general.

The same technology is also starting to be used in the medical field, where biocompatible "inks" are used to create the first cells that will be the basis of organs and part of human tissue in the not too distant future.

Characteristics of 3D printing

The features of the 3D printer are many, and in particular:

The 3D printer and the printing methods used

For each material there are different printing technologies and methodologies. Here they are:

And many other technologies, continually evolving.

Resolution and Infill

Two important parameters for the finished object are its resolution and Infill.

Resolution

Since it is a 3D model , the resolution is measured using two different factors. Linearly (X and Y) the resolution is indicated in DPI as for a traditional printer. From the point of view of the thickness, however, we consider that of the single layer, normally defined in micrometres.

The thickness factor is the most crucial one. A low resolution is indicated when the detected value is 0.3-0.4mm and a high or very high resolution when it is less than 0.1mm.

Infill

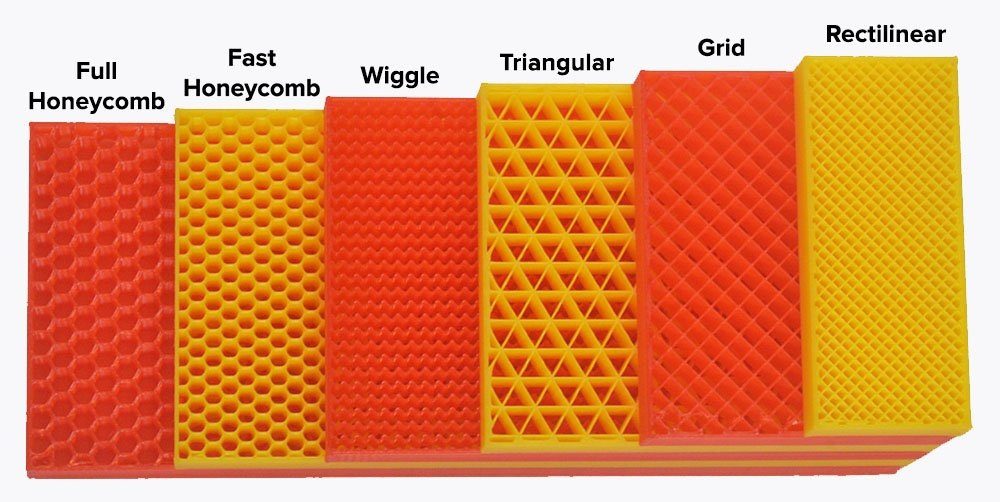

Indicates how the model is filled . In fact, it can be completely empty, completely full or with a grid.

What varies is the production cost, production time, weight and strength of the piece. The Infill value is usually indicated as a percentage.

Traditional infill methods are square mesh and honeycomb mesh. Both guarantee a good relationship between cost/production time and robustness.

Home uses

The 3D printer, as well as for industrial and prototyping uses, is highly appreciated for home or community uses. Small models are perfect tools for the needs of many industries. From model making details to furnishing accessories and jewellery, there are many non-industrial application sectors.

The presence of templates on the web and the relative ease of creating new ones has created ongoing interest in the topic, with small and large companies starting to offer printing on demand on the Internet as well.

3D printer price

3D printer price

Much interest, the fall in patents and the increasingly reduced cost of materials and design have significantly lowered the cost of printers. There are many brands, the most renowned are those that use FDM technology such as those proposed by Kentstrapper, WASP and Sharebot. Each of these brands offers 3D printers with a starting price ranging from €700 to €1500.